ENGINEERED WATERPROOF FLOORS

Engineered Waterproof Floors are known today by many names; WPC Floors, Waterproof Laminate, Engineered LVT and LVP, Waterproof Composite Floors among many other names that are all, in theory, correct.

Some others like to call them Vinyl Floors, but we think referring to them as Vinyl Floors is a little bit missing the point, and here’s why: What people have know for decades as Vinyl Floors doesn’t even start to compare with these floors. Vinyl floors used to be ugly, hard to install, poorly made and in most cases, highly toxic and unsafe. Our Waterproof Floors are completely different, that’s why we like to call them for what they truly are: Engineered Waterproof Floors.

So know that you know their true name, why are they considered so great? and why have they become so popular? Well here are some key things to understand about this wonderful product.

THE ULTIMATE FLOOR

Although FORTEM Resilient Surfaces is a new flooring brand, our team has decades of experience in the flooring industry, both from the labor part of the industry, as well as with flooring sales and distribution. Our Engineered Waterproof Floors are the result of years of feedback from flooring contractors, installers and more importantly, homeowners.

Our floors include most of the benefits of other flooring types, but without their disadvantages. For example, in case you want to install on top of an existing floor, these Waterproof Floors are as practical as a Laminate and as beautiful as a Hardwood Floor, but thanks to its narrow profile they don’t raise the height of your floor too much, so you don’t have to shave doors and cabinets. They’re also durable and waterproof like porcelain, but unlike porcelain they’re warm and comfortable to the naked foot.

We developed FORTEM Engineered Waterproof Floors to be the ultimate floor for both residential applications and commercial projects.

SUPERB CONSTRUCTION

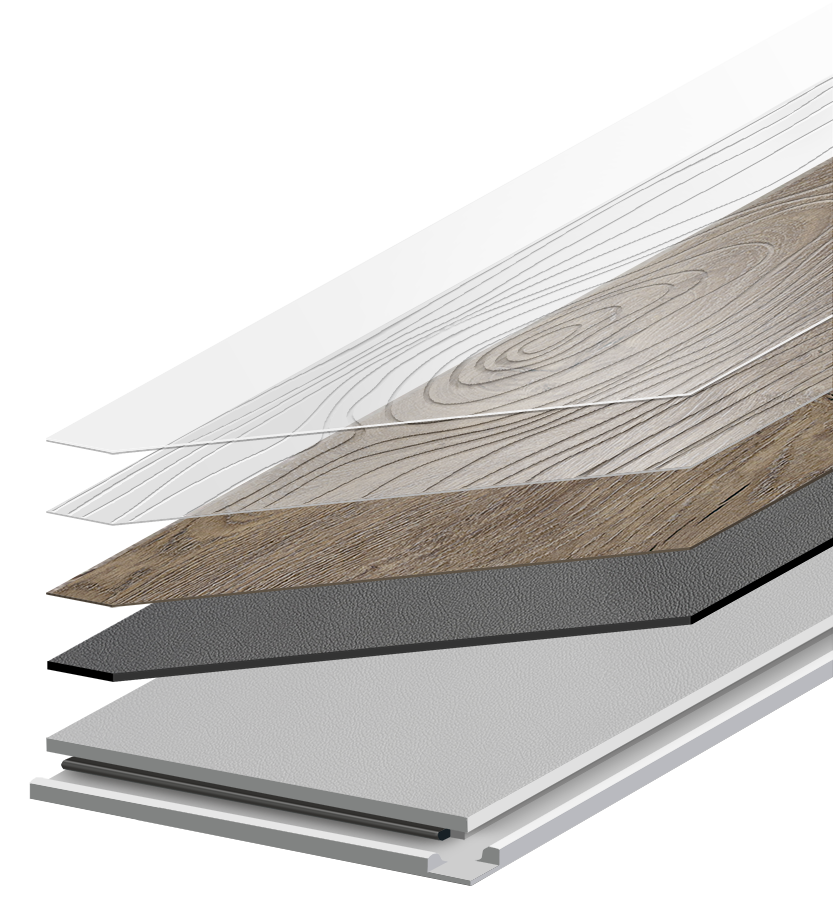

Waterproof Floors are typically comprised of 3 or 4 layers, depending on the manufacturer. The fourth layers is usually the backing of the floor or what’s known as the underlayment. Typically, this underlayment is made of a thin sheet of cork glued to the composite core. In other cases, some manufacturers choose to differentiate their product by using XLPE or EVA Foam Padding instead. We think that any of those options are deficient at best, but we’ll come back to this and explain why in the next point.

Our Engineered Waterproof Floors are comprised of only 3 layers. Here’s the breakdown.

The Composite Core

The Wood-Polymer Composite Core is the foundation of these great floors. It’s a very clever solution to the problem that water and moisture present for hardwood and laminate floors.

The Decor Layer

Is formed by fusing together 100% virgin vinyl with a hyper-realistic design film. The decor layer is what provides the incredibly beautiful looks that are identical to natural materials.

The Wear Layer

A thick, high-quality urethane coating with microscopic beads of ceramic (one of the toughest materials on earth) that provide the ultimate layer of protection (and anti-slip properties) to your floors.

ATTACHED PADDING VS DRY BACK

As mentioned before, some manufacturers choose to incorporate the underlayment directly to the plank. We think that decision is a bad one and here’s why.

THE HEALTH CONCERNS

Most Waterproof Flooring brands incorporate cork as the backing for their flooring planks. They claim that cork underlayment is naturally mold and mildew resistant, which is not wrong. But being mold and mildew resistant does not mean being mold and mildew-proof, and that’s a problem.

Eventually mold and mildew will find their way into your floors, specially given the fact that cork is extremely porous, hence it easily absorbs water and moisture. Now you can say: What about waterproof floors that use foam padding as the backing? well, that bring us to our second reason.

THE PRACTICAL REASONS

EVA (Ethylene-vinyl acetate) and XLPE (Cross-linked poly-ethylene) can be safer than Cork backing, specially when they include a moisture barrier film. But being safer doesn’t mean being a perfect solution. There’s two reasons why the attached foam padding fails by means of being impractical.

The first one is because most residential condominiums and commercial buildings follow City and State regulations when it comes to flooring installations, and the use of soundproof underlayments. This means that the general contractor needs to file test results from independent labs to prove that the underlayment specs are good enough. Most flooring brands don’t conduct these tests given the high costs associated with them. So the contractor gets stuck before starting the job and the whole renovation project gets delayed.

The second practical reason is staircases. Unlike the general areas of the project where the Engineered Waterproof Floors are meant to be installed with a floating method, on a staircase the flooring planks must be glued down or secured in some way. When you have a foam padding attached to the plank, you can’t glue them down using common flooring adhesives. So you end up needing to remove or scrape the underlayment from the flooring planks; costing you time, and likely voiding your warranty for the whole project.

For these reasons we choose not to incorporate any backing to our Engineered Waterproof Floors. Of course you need to use an underlayment when floating Waterproof Floors, and with our floors you can choose exactly the right underlayment that fits your needs and that will let you, and your contractor finish your project faster. FORTEM Engineered Waterproof Floors are well-thought through, and you can rest assured that we base our decision-making process 100% on what’s best for the end-customer, and not on what’s easier for our marketing department to sell our products.

There’s a vast selection of cork underlayments and foam padding options available in the market, but we recommend the ECLIPSE II Professional Underlayment from FOAM PRODUCTS.

FASTER INSTALLATIONS

5G® by Välinge is the brand for the globally recognized locking system used in our Engineered Waterproof Floors. With 5G®, floor installations has never been easier, or faster. This locking system is based on a single action “Drop n’ Lock” installation method that is suitable for all types and widths of flooring products. There’s no need for angle the planks to make them fit together, and you’ll never have to use a tapping block again or a pull-bar to push two planks together.

The boards are locked on the long side with a traditional angling method. On the short side is where the magic happens; here our 5G® locking system enables a simple and fast installation without the need of any tools. Our 5G® technology secures the flooring planks with a visible and audible locking function. When the plank is folded down, a flexible plastic tongue is pushed into the groove of the other plank. As the plank reaches its final position, the plastic tongue snaps out into the “counter-groove” and emits a clicking sound to lock both planks vertically.